Anniversary in Harjavalta: Flash smelting turns 70

Seventy years have passed since the historic day when the flash smelting method had its world premiere and began production at the Harjavalta smelter.

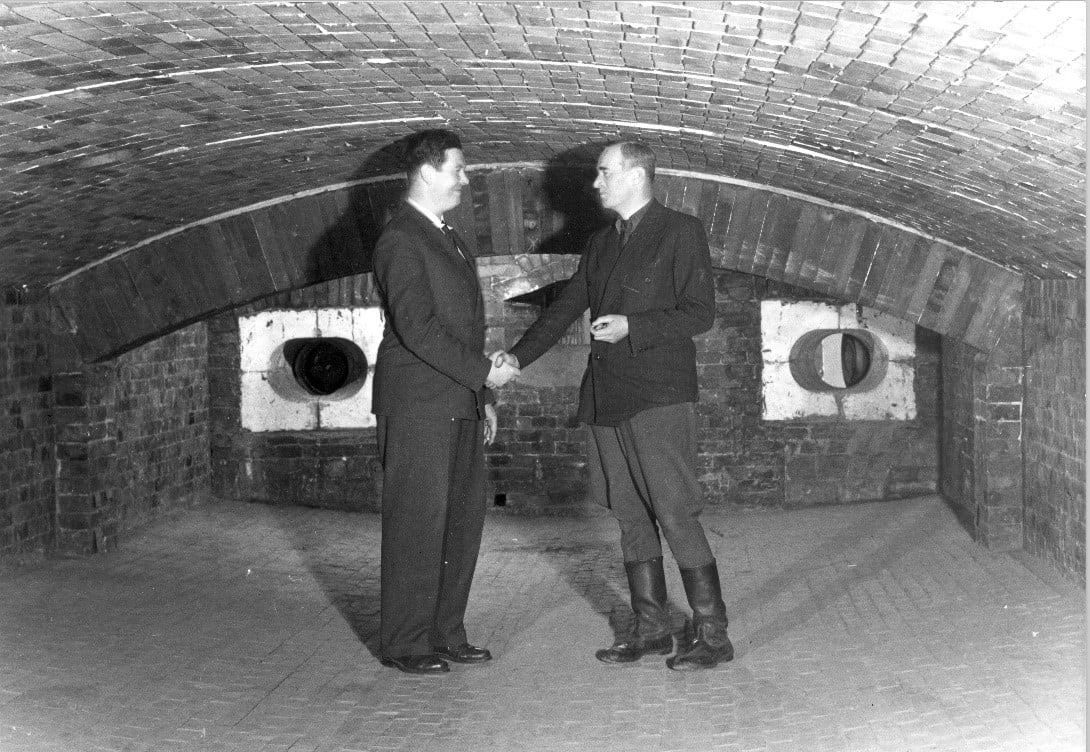

Image: The first flash furnace was completed on 23/3/1949.

"Start-up took place on the night of 20 April 1949. The second shift was waiting in the infeed. When we came on shift at six in the morning there was no fluid at all in the furnace, just a bright red pile. This was probably because of the acid, which meant smelting did not begin first. The stone was cone-shaped, so it did not come up out of the vessel either, but got stuck in the stone channel. In the beginning, we doubted that anything would come of it all. It took several months’ work before we arrived at the right method. And then it worked!"

This is how Toivo Pullinen, flash furnace manager and the first person to light the furnace, describes his feelings at that historic moment in the smelting plant.

"Our employees’ patience was sorely tried during those first flash smelting years. Maintenance personnel responded countless times at every hour of the day or night to get to grips with the method’s idiosyncratic ways. They were often forced to work under extremely difficult conditions."

Refining the new technique and overcoming the problems demanded unstinting effort far into the 1950s. Skepticism toward the method began to wane when functionality was improved, and it finally became possible to fully complete operating cycles.

In 1954, when the first license agreement was concluded with the Japanese company Furukawa, staff at the smelting plant began to feel they had created something new and valuable. When marketing efforts began in earnest on the world market, they began to investigate whether the method would also work for producing another metal – nickel.*

Today, the method constitutes a cornerstone of energy efficiency in Boliden Harjavalta’s smelting plants, and these days it is used in the production of more than half of the entire world’s copper.

Image: In the middle of the 1950s, functionality became significantly more reliable and working conditions at the plant also improved at the same time. Here we see a plant operative in the summer of 1955.

*Source: a half-century of copper and nickel, Outokumpu Harjavalta’s plants 1944–1994